SCILS AND THE CREATION OF A UNIQUE COMPANY CULTURE

In January 2019, after months of dialogue, Aker BP signed an important contract with Optime Subsea. This agreement would prove to be of huge significance for Optime and the development of SCILS.

In May of the same year, the first SCILS (Subsea Controls and Intervention Light System) from Optime Subsea was delivered to Aker BP.

– Despite the struggle of dealing with short timelines, we all had the same goal of success. Every single one of us put in a little extra. When SCILS was delivered and the goal achieved, we were all so proud to be part of the Optime winning team, says Bente Dysthe, Human Resources and HSE Manager.

A SMALL SOLUTION FOR CONTROLLING BIG TECHNOLOGY

– Despite the struggle of dealing with short timelines, we all had the same goal of success. Every single one of us put in a little extra. When SCILS was delivered and the goal achieved, we were all so proud to be part of the Optime winning team, says Bente Dysthe, Human Resources and HSE Manager.

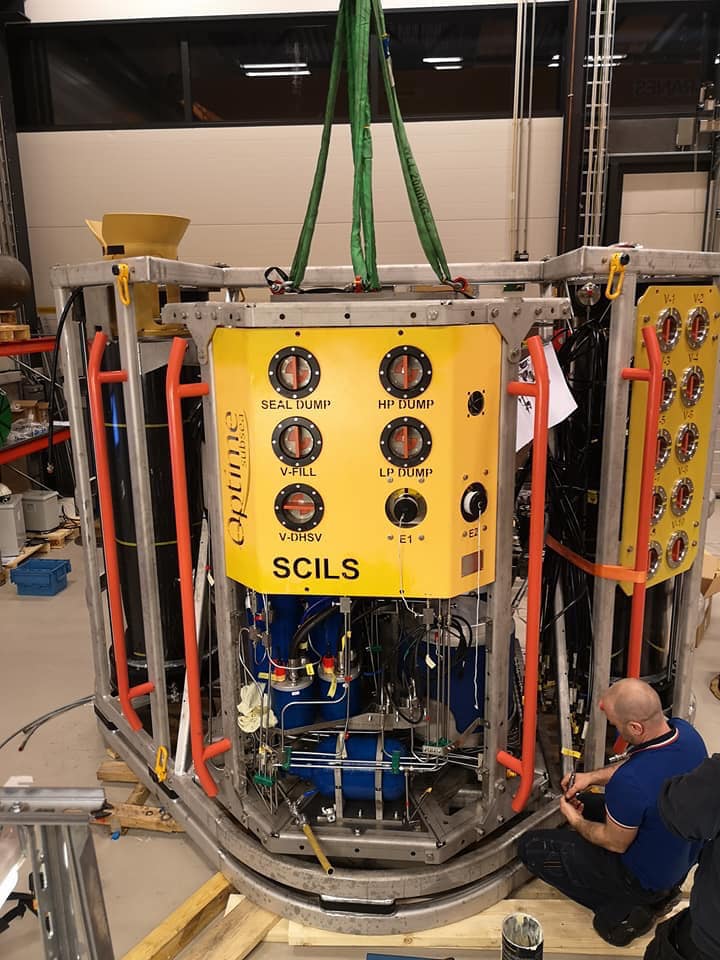

SCILS is an advanced control system to manage deep-sea well functions. The devices measure only 3.5 x 2.5 meters, with a weight of approximately 7 tonnes.

– It is fascinating that a small SCILS unit can manage such large technology, states Optime Subsea and SCILS designer, Dag Borgen.

– As a designer, I want our products and solutions to look good and, of course, it is also important that they are user friendly, Dag Borgen explains.

SCILS AS IT STANDS TODAY, IS VERSION NUMBER TWO

The actual concept of SCILS started in the early days of Optime Subsea, back in 2015 with the first SCILS launched at the Subsea Valley conference in 2018.

EXCITING TIMES AT OPTIME SUBSEA

According to the people who work there, Optime Subsea can be a very stimulating workplace. But after the agreement with Aker BP in January 2019 it was the beginning of especially exciting times. SCILS would finally prove its value, and it was scheduled to be deployed at the first Aker BP rig in June 2019, barely a few months after the contract was signed. This schedule would soon become even tighter.

Service Engineer Tom Ole Raaen started working at Optime Subsea in February 2019. He was one of several Optime Subsea employees present at the rig when SCILS was deployed for the first time. Tom Ole remembers the hectic situations in the workshop. They didn’t have much time, and it didn’t get any easier to meet the deadline when the delivery was moved from June to May. Despite all this, the SCILS unit was ready for service in May 2019, only four months after the contract was signed.

– Out there at the rig, I was convinced that we were well prepared, despite the short timelines. I wasn’t concerned that something could go wrong, Tom Ole remembers.

The mobilisation of the SCILS onboard Deepsea Nordkapp went well. Traditional systems take many days to mobilise. The SCILS mobilisation was finished within one day. Before equipment can be run into operations it has to be tested on deck, the first testing of the SCILS onboard the rig should be both challenging and nerve-wreaking.

– When it was time to power the device on, we had some challenges, and I became a bit nervous. But with tremendous support from the onshore team and the “One Team” spirit at Aker BP, we managed to fix it, and our clients at Aker BP were happy, Tom Ole says.

The unit then began its descent, but it took some time before the SCILS had found its place on the seabed.

– Out there at the rig, I was convinced that we were well prepared, despite the short timelines. I wasn’t concerned that something could go wrong, Tom Ole remembers.

BELIEVING AND TAKING A CHANCE

The first SCILS unit developed by Optime, before the contract with Aker BP was signed, looked quite different from the SCILS units in use today.

– We were taking a big chance making that prototype of SCILS in a recession. But no one was willing to buy the new solution without having seen it first, shares Bente.

When Optime Subsea got that all-important contract with Aker BP, the work of designing the SCILS as it is today started. The changes were based on a requirements specification from Aker BP.

– There are about 120 new pipes in the latest SCILS, which weren’t there in the existing system. It was quite a job to make it fit. The changes from that first prototype of SCILS are considerable, Dag explains.

– Back then, we moved Dag’s office down to the workshop. We were tired of walking the stairs up to his office asking for design input, because we were building and designing at the same time, Tom Ole adds.

As a newly employed purchaser at the time, Stine Therese Timland was concerned about getting the right parts in time.

-Making the SCILS ready for service was like a big puzzle. It was a tight schedule, and I was worried some of the parts might arrive too late, Stine Therese says.

– But we made it. I love SCILS, and I believe every one of us here at Optime Subsea, feels an ownership to the solution, Stine Therese concludes.

FLAT STRUCTURE AND A DOSE OF CRAZINESS

Why did Optime Subsea succeed with SCILS? Is it the leadership, the company culture or something else?

– At Optime Subsea we do it the best way, no matter who comes up with the idea. I believe that characterizes our product development and is one of the reasons for our success, Tom Ole says.

– The company culture initiated by management is filled with enthusiasm and pure happiness over the success we have had so far. All our products and solutions contain a dose of craziness, or maybe we can call it innovation, adds Dag.

Since the signing of the contract, both Aker BP and Optime Subsea have continued working as a team with SCILS.

– Aker BP did trust in Optime Subsea and SCILS. It is rewarding to get the opportunity to launch new technology the way we have done with SCILS. For me, Optime Subsea so far has been an industrial adventure of a workplace, the designer continues.